The air conditioner at home suddenly stopped working, and all the lights flickered and then went out behind this seemingly ordinary tripping phenomenon, in fact, there is a “race against time” of circuit protection devices at critical moments. In this race against the current, the knife type contact fuse, with its sensitive response ability, can instantly cut off the circuit, effectively preventing fire hazards and equipment damage. The unique structural design and excellent breaking performance of the fuse, make it favored by engineering technicians, and become a reliable barrier for the safety protection of electrical systems.

How Does a Knife Blade Fuse Achieve Rapid Power Cutoff in Overload Protection?

The knife type fuse is mainly composed of a fuse wire, a fuse holder, and a fuse housing. Among them, the fuse wire is made of conductive materials and has the characteristic of a low melting point. When current flows through the fuse wire, the fuse link will gradually melt due to heating until the circuit is finally disconnected. The fuse holder, as a fixed support component for the fuse core, ensures the stable operation of the fuse, through close contact with the fixing nut between it and the fuse core. The role of the fuse housing is to protect the fuse wire and prevent electric shock accidents. It is usually made of insulating materials.

In the overload state, the principle of power off of the fuse type knife switch is as follows: Once the current in the circuit exceeds the rated current of the fuse wire, the heating speed of the fuse wire will increase. As the current rises, the temperature of the fuse link also rises. When it reaches its melting point, the fuse wire will melt and cut off the circuit, thus protecting the electrical equipment from being damaged by excessive current.

In the short circuit state, the knife type fuse can also achieve the power off function. When a short circuit occurs in the circuit, the current will increase sharply in an instant. Due to the transient characteristics in the short circuit process, the current rises very fast, which causes the temperature of the fuse wire to quickly exceed the melting point. After the fuse wire melts, the circuit is cut off, thus preventing the fault from further expanding and causing more serious damage.

The power off mechanism of the knife type fuse is based on the characteristics of the fuse wire, precisely controlling the melting time of the fuse wire by controlling the current size. The rated current of the fuse wire is selected, according to the rated current of the electrical equipment to be protected, and it is generally reasonably selected in combination with factors, such as the load characteristics and working environment of the circuit.

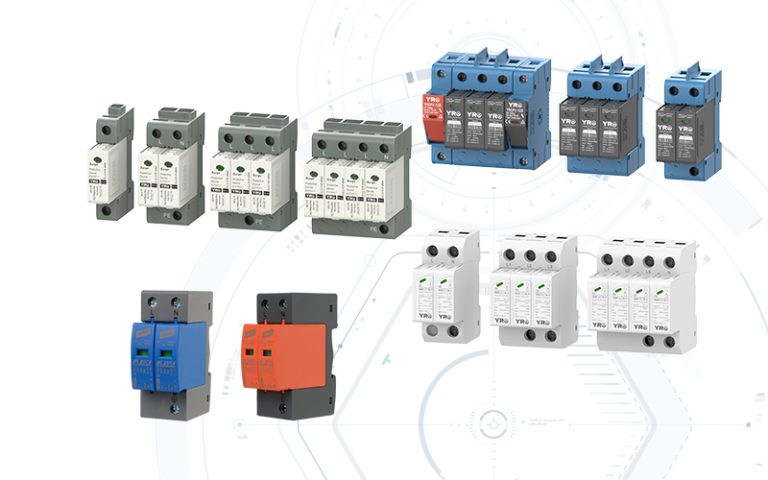

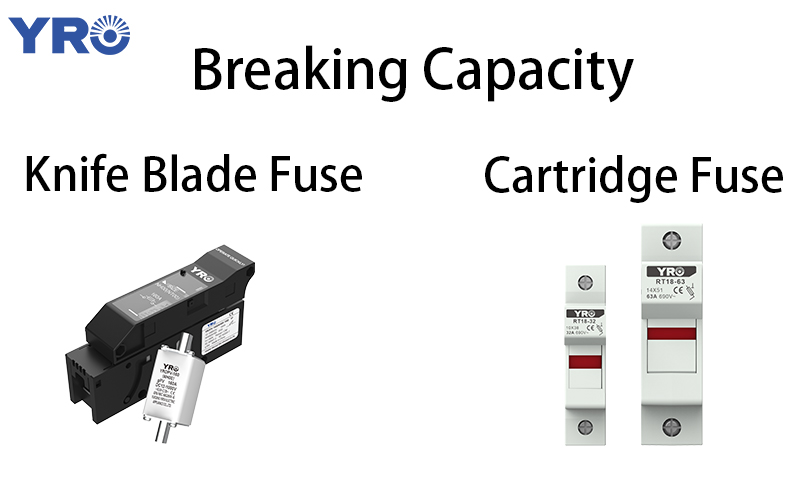

How Does a Knife Blade Fuse Compare to a Cartridge Fuse in Terms of Breaking Capacity?

1. Basic characteristics of tubular fuses

Tubular fuses are made of glass or ceramic core components, and operate similarly to knife type contact fuses, in that they isolate circuits by the rapid melting of the fuse body. This type of fuse is often used in residential and low voltage power distribution scenarios, because of its simple construction and the fact that the fuse status can be recognized directly by its appearance. However, when dealing with high current inrush, high voltage conditions or complex electromagnetic environments, their current interrupting efficiency and fault protection capabilities have obvious shortcomings.

2. Advantages of knife type contact fuses in breaking capacity

(1) Greater breaking capacity

Due to the adoption of a knife type contact design, the knife type contact fuse can quickly separate the contacts and form a large air gap when breaking the circuit. This larger gap helps to quickly break the arc, preventing the arc from continuously burning or reigniting the circuit. This design enables it to effectively interrupt the circuit when facing high fault currents, showing stronger breaking capacity and higher arc extinguishing efficiency.

(2) Good mechanical stability and repeatability

In the design and manufacturing process of the knife blade fuse, high requirements are placed on the stability and consistency of the mechanical structure. Its precise knife type structure can ensure, that each product has similar power off response and breaking capacity during mass production, thus maintaining good safety performance in long term use.

(3) Higher arc extinguishing efficiency

During the contact separation process of the nh fuse, through the design of a reasonable air gap and current guiding channel, the arc generated during disconnection can be quickly elongated and extinguished. The efficiency of arc extinction is directly related to the safety performance of the fuse. Quickly extinguishing the arc can effectively prevent arc reignition and electrical fires.

3. Comparison in application environments

In actual power distribution and industrial control systems, circuits often face sudden overloads or short circuit situations. Due to its rapid power off and strong breaking capacity, the blade contact fuse can interrupt high fault currents in a very short time, protecting equipment and lines from damage. Although tubular fuses perform stably in low current and low voltage environments, they have certain limitations in breaking speed and arc extinguishing ability when dealing with high energy faults. Therefore, for high performance and high safety electrical systems, the knife switch fuse can undoubtedly meet the strict requirements of modern industry and power systems for protective devices.

Conclusion

From Edison’s carbonized bamboo filament fuse in the 19th century to today’s intelligent fuses with millisecond level response, humanity has continuously broken through physical limits in the field of circuit protection. With its unique knife type structure and the application of low melting point metal materials, the knife type contact fuse can achieve rapid power off in overload protection, ensuring that the circuit is quickly disconnected when a fault occurs, thus effectively protecting the safety of electrical equipment and systems. For power systems, industrial automation, and high end electronic devices, choosing the right fuse can not only improve system safety but also increase overall operating efficiency. Driven by the continuous pursuit of safety and efficiency, the knife type contact fuse has broad development prospects, and will play an increasingly important role in the future of electrical protection.