A knife blade fuse is a type of electrical fuse used to protect electrical circuits from overcurrent conditions. It consists of a flat, blade-like metal strip, typically made of a material with a low melting point, such as copper or zinc. This strip is enclosed within a fuse holder or a fuse box.

The purpose of a knife blade fuse is to interrupt the flow of electrical current in the event of an overcurrent or a short circuit. When the current passing through the fuse exceeds its rated capacity, the metal strip in the fuse heats up and eventually melts, breaking the electrical connection. This action effectively disconnects the circuit, preventing damage to the electrical components and devices downstream.

Knife blade fuses are commonly used in automotive applications, electrical panels, and various industrial settings. They come in different sizes and current ratings to match the specific requirements of the circuit they protect. These fuses are easy to replace when they blow, making them a convenient choice for circuit protection.

What is the use of blade fuse?

Blade fuses serve a critical role in electrical and electronic systems by providing protection against overcurrent conditions. Here are some common uses and applications for blade fuses in various industries:

Automotive Industry: Blade fuses are extensively used in automobiles to protect electrical circuits and components. They can be found in fuse boxes within the vehicle. They safeguard systems such as lighting, heating, air conditioning, radios, power windows, and more. If a circuit experiences an overload or short circuit, the blade fuse will blow, preventing damage to the vehicle’s electrical system.

Industrial Equipment: Blade fuses are employed in industrial machinery and equipment to safeguard against electrical faults. They protect motors, control panels, and other electrical components from excessive current, which could lead to damage or fire hazards.

Marine Applications: Boats and marine vessels use blade fuses to protect electrical systems on board. They ensure the safety and reliability of various marine electronics, including navigation systems, lighting, and communication equipment.

Consumer Electronics: Blade fuses are utilized in consumer electronics, especially larger appliances and equipment. They provide an additional layer of safety by preventing electrical fires or damage due to overcurrent situations.

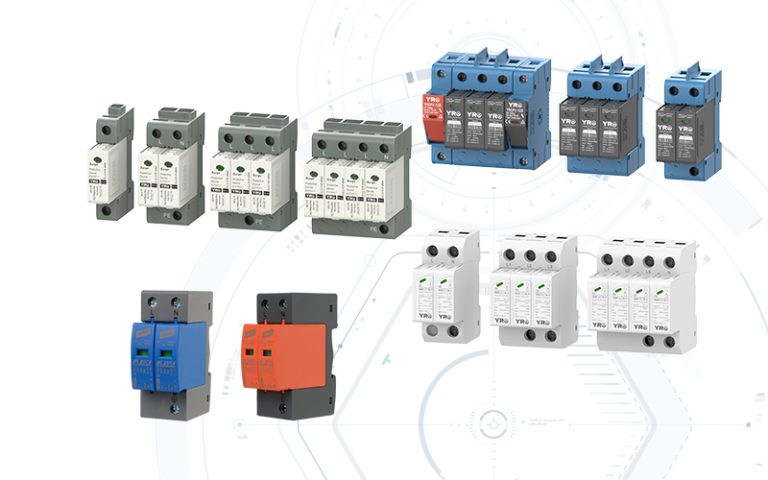

Power Distribution: In residential and commercial buildings, blade fuses are sometimes used in power distribution panels. They help protect individual circuits within the building from overloads, ensuring the safety of occupants and preventing damage to electrical appliances.

Recreational Vehicles (RVs): RVs often rely on blade fuses to protect their electrical systems and accessories, such as refrigerators, air conditioners, and lighting, while on the road or at campsites.

Electronics Manufacturing: Blade fuses are used during the manufacturing of electronic devices to ensure that circuits are protected from excessive current during testing and quality control processes.

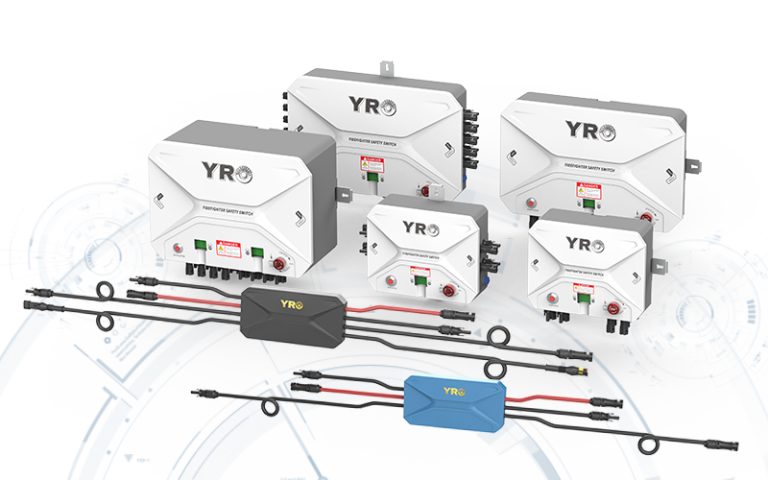

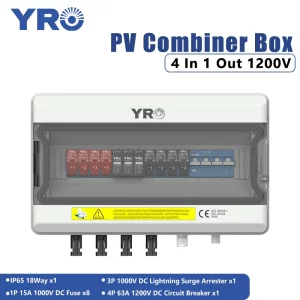

Renewable Energy Systems: In solar and wind energy systems, blade fuses play a role in protecting critical components like inverters, charge controllers, and battery banks from electrical faults.

In all these applications, the primary purpose of blade fuses is to prevent overcurrent conditions from causing damage, fires, or electrical hazards. They are an integral part of electrical safety and are designed to be easily replaceable when they blow, restoring the circuit’s functionality.

Enhanced Safety: Incorporating knife blade fuses into your equipment or products ensures that they are protected against overcurrent conditions, reducing the risk of electrical fires, damage, and potential liabilities.

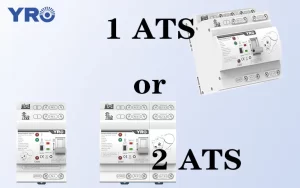

Reliability: Knife blade fuses offer quick and reliable protection, minimizing downtime and maintenance costs. This reliability can be a valuable selling point for your products or services.

Ease of Maintenance: With their user-friendly design, knife fuses are easy to replace when they blow. This can reduce the need for specialized technicians and lower overall maintenance expenses.

Industry Standardization: Knife blade fuses follow industry standards for sizes and ratings, making them compatible with a wide range of applications. This standardization can simplify the design and integration of your products.

Space Efficiency: The compact design of knife blade fuses saves space in your equipment or systems, allowing for more efficient use of available space.

Cost-Effectiveness: Utilizing knife fuses can help you keep production costs in check while ensuring that your products meet safety standards and regulations.

Versatility: Knife blade fuses can be used in various industries and applications, making them a versatile choice for protecting your electrical systems or devices.

Environmental Durability: Many knife fuses are designed to withstand harsh environmental conditions, ensuring that your equipment remains reliable in challenging situations.

Visual Indication: Consider using knife blade fuses with transparent windows that provide visual indication of their status. This can make it easier for maintenance personnel to identify and replace blown fuses quickly.

Safety Documentation: When incorporating knife fuses into your products, ensure that you provide clear documentation and instructions regarding fuse replacement and maintenance. This can enhance your product’s user-friendliness and safety.